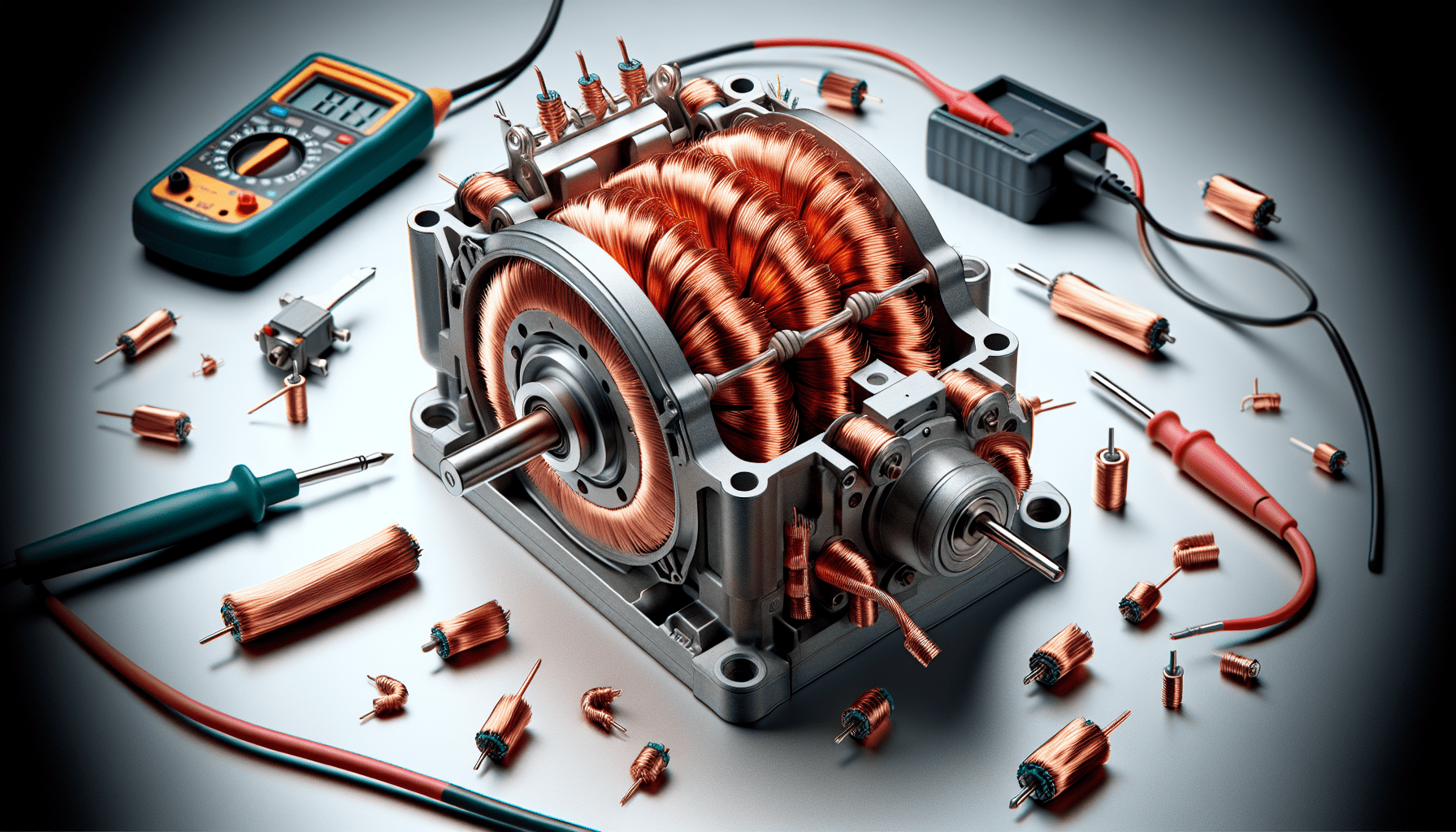

Have you ever wondered what the best motor for a DIY generator is? Whether you’re a hobbyist looking for your next project or someone interested in creating a backup power source, choosing the right motor can make all the difference. But with so many options available, how do you decide which is best for your needs?

Understanding The Basics of Motors for DIY Generators

Before you jump in and purchase a motor, it’s crucial to understand some basic concepts. After all, knowledge is power!

What is a Generator?

A generator is a device that converts mechanical energy into electrical energy. This process is facilitated by a motor, which is the heart and soul of the generator.

Why Build a DIY Generator?

DIY generators can be a fun and rewarding project. They can also be practical, providing a backup power source during emergencies or powering gadgets in remote locations.

Generators vs. Motors

It’s easy to get confused between generators and motors. While they perform different functions, they have a symbiotic relationship. Motors convert electrical energy into mechanical energy, while generators do the opposite. When selecting a motor for your DIY generator, understanding this relationship is crucial.

Types of Motors Suitable for DIY Generators

There are various types of motors you can use for your DIY generator, each with unique features and advantages.

AC Motors

AC motors run on alternating current and are commonly used in household appliances and industrial equipment.

Advantages

- High Efficiency: AC motors are generally more efficient than DC motors.

- Long Lifespan: These motors are durable and built to last.

- Availability: Easier to find and purchase.

Disadvantages

- Complexity: AC motors are more complex and usually require an inverter.

- Cost: Generally more expensive.

DC Motors

DC motors run on direct current and are commonly found in battery-operated devices, such as electric vehicles and portable electronics.

Advantages

- Simplicity: Easier to understand and modify.

- Cost: Generally cheaper than AC motors.

- Battery Compatibility: Easily integrates with battery systems.

Disadvantages

- Efficiency: Slightly less efficient compared to AC motors.

- Lifespan: Typically have a shorter lifespan.

Universal Motors

Universal motors can run on both AC and DC, making them versatile options for DIY projects.

Advantages

- Versatility: Can operate on both AC and DC.

- High Speed: Often have high RPM ratings, making them effective for generating higher power.

- Compact Size: Usually smaller and lighter.

Disadvantages

- Noise: Can be quite noisy.

- Maintenance: Requires frequent maintenance.

Stepper Motors

These motors move in small, precise steps and are typically used in applications requiring detailed control, such as 3D printers and CNC machines.

Advantages

- Precision: Offers highly accurate control.

- Reliability: Very durable and long-lasting.

Disadvantages

- Complexity: Requires a complex controller.

- Cost: Can be more expensive due to the need for additional components.

Factors to Consider When Choosing a Motor for Your DIY Generator

Now that you have a general understanding of the types of motors you can use, let’s dive into the factors you should consider to make the right choice.

Power Output

The motor’s power output is a critical factor. You’ll want to choose a motor that can generate enough power to meet your needs.

| Motor Type | Typical Power Output Range |

|---|---|

| AC Motor | 0.5 to 50 HP |

| DC Motor | 0.1 to 10 HP |

| Universal Motor | 0.25 to 15 HP |

| Stepper Motor | 0.01 to 2 HP |

Efficiency

Efficiency is essential for getting the most out of your generator. Generally, AC motors have higher efficiency ratings than DC motors, but this isn’t universally true. Always check the motor’s efficiency rating before purchasing.

Voltage Compatibility

Ensure the motor you choose is compatible with your power source’s voltage. Using a motor with incompatible voltage can result in reduced efficiency or even damage to the motor and generator components.

Speed and Torque

Speed and torque are essential parameters to consider. If your generator requires high-speed rotations, motors with high RPM ratings are ideal. Similarly, if your application needs higher torque, choose a motor optimized for that purpose.

Cost and Budget

Your budget will significantly influence your choice. Fortunately, there are options available for all budget levels, whether you’re looking to spend a little or a lot.

| Motor Type | Cost Range ($) |

|---|---|

| AC Motor | 50 to 2000 |

| DC Motor | 20 to 500 |

| Universal Motor | 30 to 300 |

| Stepper Motor | 10 to 150 |

Ease of Installation

Ease of installation is another important consideration. Some motors are plug-and-play, while others may require extensive modifications and additional components.

Availability of Spare Parts

It’s always wise to consider the availability of spare parts. Opt for motors that have readily available parts to ensure easy maintenance and repairs.

Durability and Maintenance

Finally, consider the motor’s durability and maintenance needs. A durable motor will last longer and require fewer repairs, saving you time and money in the long run.

Popular Motors for DIY Generators

While there are many motors to choose from, a few stand out as popular choices among DIY enthusiasts.

Permanent Magnet DC (PMDC) Motor

PMDC motors are a favorite among DIYers because they combine simplicity, efficiency, and cost-effectiveness. These motors use permanent magnets to generate a magnetic field, eliminating the need for external power.

- Power Output: 0.1 to 5 HP

- Efficiency: 80-90%

- Cost: $50 to $300

Car Alternators

Believe it or not, car alternators are commonly repurposed for DIY generators. Highly reliable and widely available, they can be a cost-effective choice.

- Power Output: 50 to 150 Amps

- Efficiency: Around 70%

- Cost: $20 to $150

Induction Motors

Induction motors are often used because of their high efficiency and durability. They usually require an inverter to work effectively in a generator setup.

- Power Output: 0.5 to 30 HP

- Efficiency: 85-95%

- Cost: $100 to $1000

Tips for Building Your DIY Generator

Armed with your motor choice and a solid understanding of the fundamentals, you’re ready to start building your DIY generator. Here are some tips to help you along the way.

Plan and Research

Before you begin, conduct thorough research and plan your project. Understanding the requirements and potential challenges will save you time and money.

Gather Your Materials

Aside from your motor, you’ll need other components such as a frame, wiring, a voltage regulator, and possibly an inverter. Make a checklist and gather all materials before starting.

Safety First

Safety is paramount. Always wear appropriate safety gear, understand the risks involved, and follow safety protocols to avoid injuries.

Test and Troubleshoot

After assembling your generator, perform extensive tests to ensure everything works correctly. Identify and troubleshoot any issues early to avoid future problems.

Regular Maintenance

Once your generator is up and running, regular maintenance is essential to keep it functioning efficiently. Clean components, check for wear and tear, and replace parts as necessary.

Common Pitfalls to Avoid

Even the most careful planning can sometimes go awry. Here are some common pitfalls to watch out for.

Overloading The Motor

One of the most common mistakes is overloading the motor, which can lead to overheating and eventual failure. Make sure the motor you choose can handle the required power output.

Ignoring Voltage Ratings

Using a motor with incompatible voltage ratings can damage both the motor and other components in your generator. Always double-check voltage compatibility.

Poor Connections

Loose or poor electrical connections can result in inefficient operation or even complete failure. Ensure all connections are secure and well-insulated.

Insufficient Maintenance

Failing to perform regular maintenance can shorten the lifespan of your generator. Stick to a maintenance schedule to keep everything running smoothly.

Real-World Examples

To illustrate the practical application of these concepts, let’s look at a couple of real-world examples of DIY generators.

Example 1: Bicycle-Powered Generator

A common and straightforward DIY project is a bicycle-powered generator using a Permanent Magnet DC (PMDC) motor. In this setup, the bicycle’s rear wheel drives the motor, generating electricity as you pedal.

- Motor Used: PMDC Motor

- Cost: Around $100

- Output: Typically powers small electronics like LED lights and mobile chargers

Example 2: Solar-Powered Generator

Another popular project is a solar-powered generator using a car alternator. Solar panels charge a battery, and the alternator helps convert this stored energy into usable electricity.

- Motor Used: Car Alternator

- Cost: Around $200 including solar panels

- Output: Can power small household appliances

Advanced Considerations for Enthusiasts

If you’re more experienced or looking to push the boundaries, here are some advanced considerations.

Hybrid Systems

Combining different types of motors and power sources can create more versatile and efficient systems. For instance, pairing a solar panel with a wind turbine can ensure continuous power supply in varying weather conditions.

Smart Controllers

Integrating smart controllers can optimize your generator’s efficiency and make it easier to monitor. These controllers can automate functions such as voltage regulation and power distribution.

Energy Storage Solutions

Effective energy storage solutions like lithium-ion batteries can significantly enhance your generator’s usability. These batteries offer higher energy density and longer lifespan compared to traditional lead-acid batteries.

Custom Fabrications

For those with the skills and tools, custom fabrications can tailor your generator to better meet specific needs. Custom frames, enclosures, and cooling systems can optimize performance and durability.

Conclusion

Creating a DIY generator is an exciting and rewarding endeavor, but choosing the right motor is essential for success. Whether you opt for an AC motor, DC motor, universal motor, or a stepper motor, understanding the pros, cons, and practical considerations will guide you to the best choice for your project. Remember to plan carefully, prioritize safety, and perform regular maintenance to keep your generator running smoothly for years to come. With the right motor and a little bit of know-how, you’ll be well on your way to generating your own power and perhaps even sparking a deeper interest in the fascinating world of electrical engineering.